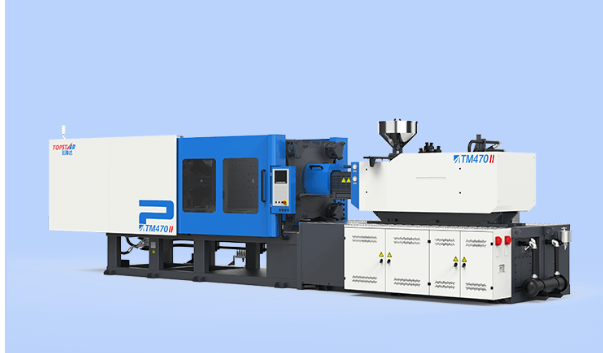

Selecting a plastic injection molding machine for large part molding is a systematic design exercise that involves matching the part geometry, material properties, target cycle time, and production economics with the machine’s clamping force, injection capacity, platen size, and auxiliary systems. In practical terms, if buyers view this selection as a series of measurable trade-offs—such as projected part area, required shot size, injection pressure, mold footprint, and target cycle time—then reliable production and predictable unit costs can be achieved. For example, a typical large consumer electronics housing measuring 24 inches by 18 inches, molded from engineering thermoplastics at moderate injection pressures, may require a machine with clamping forces of hundreds or even thousands of tons. Selecting a machine with insufficient clamping force or an inappropriate platen opening can quickly lead to compromised quality or mold redesign.

Plastic Injection Molding Machine: Defining Large Part Requirements: Geometry, Tolerances, and Material Selection

Before considering a machine, first define the part: its external dimensions, projected area, gross and net wall thicknesses, critical tolerances, surface finish, and resin type (PP, ABS, PA6, PC, glass-filled grades, etc.). Large parts often have thin-walled sections to conserve material, long runners that increase injection pressure, and multi-feature geometries that require uniform cooling. For example, a 24-inch x 18-inch part with an average wall thickness of 3 mm presents different challenges than a large 48-inch x 24-inch part with thick ribs. Furthermore, it’s essential to clarify the desired cosmetic quality, as gating, mold venting, and mold design constraints influence machine selection.

The material is crucial. Engineering polymers (PC, ABS, PPS, PPA) require higher melt temperatures and may exhibit higher viscosities, which increases the pressure required for injection and affects shot size. Glass- or mineral-filled grades increase viscosity and lead to increased screw/nozzle wear; therefore, hardened steel and protective coatings are recommended for the injection unit. Finally, determine production output and target cycle time in advance: low production volumes and long cycle times may require smaller…

Calculating the clamping force, mold area, and safety margin for a plastic injection molding machine

For plastic injection molding machines used for large parts, clamping force is the most critical dimensional parameter. Projected area refers to the total area over which the plastic is subjected to pressure. Cavity (injection) pressure varies depending on the material and flow length. For many large-part applications, a reasonable starting estimate is between 3,000 and 8,000 psi, with higher pressures recommended for filled or high-viscosity materials. For example, a 432-square-inch part at 6,000 psi produces 1,296 tons of force. This calculation illustrates why large parts typically require an injection molding machine in the 500-to 1,600-ton range. However, you should always consider a design safety margin, which is a 10% to 30% buffer to account for pressure fluctuations, non-ideal venting, and shear/warpage.

When calculating clamp force, it is also necessary to consider the platen size and tie-bar spacing. The designer must size the mold to fit the platen and allow sufficient overhang for cooling manifolds and ejection systems. Also, check the clamp force distribution—hydraulic and electric toggle machines behave differently under eccentric molding loads.

Specifying the Injection Unit, Shot Volume, and Screw Design

The injection unit must deliver the required shot volume within the required cycle time and provide the plasticizing capacity to ensure consistent melt quality. Key specifications for plastic injection molding machines include maximum shot volume, injection pressure, injection speed, screw aspect ratio, and available screw diameter. Generally, the selected injection unit should be 15% to 30% larger than the maximum part shot volume to avoid frequent full strokes and account for process variations and future part changes. For example, if your part shot volume is 150 grams, specify a unit that can reliably handle 170% to 200% of that volume per shot.

Screw geometry is crucial: a higher aspect ratio improves melting and homogenization of crystalline or glass-filled resins; a dedicated barrier screw or mixing screw reduces unmelted components and improves melt flow rate stability. For abrasive or highly filled materials, use a hardened screw/barrel assembly and consider nitrided surfaces or protective coatings. In short, match the shot size, screw type, and nozzle system to your material and production targets, and always allow for margin in production capacity to ensure stable production.

Selecting a Plastic Injection Molding Machine Type, Drive, and Energy Considerations

For extensive part molding, choosing the drive type (hydraulic, all-electric, or hybrid) is crucial. Historically, hydraulic presses have dominated high-tonnage applications due to their cost-effectiveness in providing high clamping forces and fast injection speeds. However, all-electric injection molding machines are now available in a significant range of tonnages and offer excellent repeatability, lower energy consumption, and cleaner operation. Hybrid machines combine the hydraulic power of clamping and hydraulic amplification with electric control of screw and platen movement, achieving a balance between power density and efficiency.

Consider energy and uptime: All-electric injection molding machines typically use 20% to 50% less energy than equivalent hydraulic presses because they consume electricity only when moving the axes. Furthermore, these energy savings become crucial in long-term production runs, contributing to the achievement of sustainability goals. Meanwhile, for extensive tonnage parts where a fully electric solution is impractical or prohibitively expensive, efficient servo-hydraulic systems with energy recovery and variable displacement pumps can improve efficiency while maintaining the original clamping force.

Mold Interface, Cooling Strategy, and Mold Handling

The mold-machine interface determines whether theoretical clamping force and injection capacity can be translated into repeatable production. For large parts, heavy-duty molds should be planned: specify platen load ratings, appropriate lifting equipment, and safe mold change procedures. Ensure that the plastic injection molding machine’s platen hole pattern and tie-bar spacing are compatible with the mold base; if necessary, select a machine with an adjustable bolt hole pattern or a custom baseplate.

Cooling strategy is crucial. Long flow lengths and thick sections can create hot spots, which can increase cycle time and cause warpage. Implement optimized cooling measures—using conformal cooling whenever possible, using high-conductivity inserts for localized heat dissipation, baffles/spiral channels, and multiple temperature-controlled zones—to shorten cycle times and control shrinkage variations. The mold designer should include a manifold design that sizes the hot runner system to maintain uniform temperatures within the large gates. Additionally, the designer must create venting that prevents micro-flash and short shots without compromising the surface finish.

Making the Right Choice

Selecting a plastic injection molding machine for extensive part molding is a strategic engineering purchase that critically translates part requirements into machine and mold specifications. This begins with accurately defining the part geometry and material. Engineers must calculate the clamp force using the projected area and expected cavity pressure, with an appropriate safety margin. They must determine the size of the plastic injection molding machine’s injection unit and select a screw geometry that meets melt quality and shot size requirements. They also need to evaluate machine types based on tonnage, energy consumption, and control requirements. Simultaneously, they need to design the mold-machine interface and develop a comprehensive cooling and mold handling plan. They must also integrate automation and inline quality systems to ensure sustainable and repeatable production.